Gaskets: Basic Elements Providing Sealing and Insulation

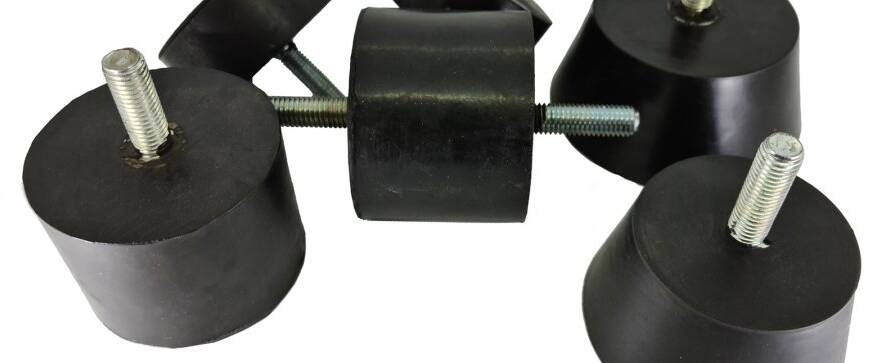

Gaskets are used to prevent liquid and gas leaks between overlapping plumbing or machinery components. These panels facilitate the fitting of the components, providing sealing and insulation.

Sealing Elements and Areas of Use

Gaskets are manufactured from a variety of materials, each designed for specific applications:

- Leather: Used in pipelines in cold regions.

- Cork: It is widely used in the bottle industry and is resistant to temperatures up to 150°C.

- Felt: Preferred in pipelines.

- Lead: Used in hydraulic systems, but limited due to its high cost.

- Plastic: Used in pipelines, glass and automotive industries.

- Asbestos: It was formerly used in steam pipelines, but is no longer preferred due to health risks.

- Paper: Used in various pipelines and building insulation.

- Chemicals: Used to provide resistance on metal surfaces and pipelines.

Selection of Seals

Seals should be selected based on the temperature and pressure of the fluid to which they are connected. The main types of seals are:

- Sealing Sheet

- Spiral Wound: Invented by Flexitallic in 1912.

- Steel Clad Asbestos

- Ring-Joint: Preferred for high pressure and temperature. These are the best spiral wound gaskets after ring-joints.

Areas of Use

Gaskets are frequently used in the following areas:

- Automotive

- Watercraft

- Industrial Applications

- Heating and Cooling Systems (HVAC)

- Electricity and Electronics

Seals are critical to preventing the leakage of fluids in liquid, gas, and solid forms and are used safely in a variety of industries.