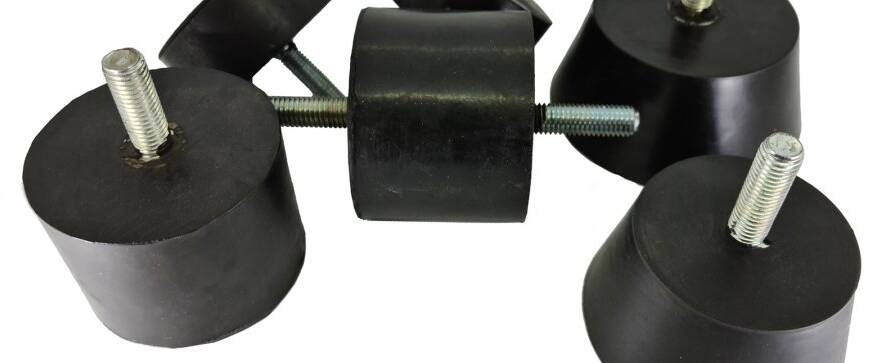

A coupling is a crucial component used to transmit motion from one machine part to another. Couplings, which transfer rotational motion generated by one power source to another, are manufactured from materials such as rubber or membrane to absorb vibrations generated within the system. Mechanical vibrations pose a risk of damage to the machine during movement, so proper coupling selection is crucial.

Things to Consider When Choosing a Coupling

Personnel selecting couplings must have sufficient knowledge of the intended use, environmental conditions, system characteristics, and coupling types. The appropriate coupling type is selected by determining the maximum required axial and angular misalignments, along with the system's power rating. The coupling acts as a safety measure for the system; therefore, selecting a torque exceeding the required torque can cause various damages to the system. When selecting a gear coupling, the materials used and the heat treatment applied should also be considered.

Coupling Usage Areas

Couplings can be used wherever power transmission is required. They are preferred wherever motors are used, such as in traction and lifting equipment and pump systems, depending on simple or complex requirements. For example, they can be used at the entrance to the main lifting assembly of a 250-ton crane, as well as in a water pump.

Importance and Features of Couplings

Although small in size and cost, couplings play a significant role in the manufacturing process. They must be easy to connect and disconnect; they also allow for some degree of misalignment between two adjacent shafts. The purpose of a coupling is to minimize residual misalignment in the running motion to optimize power transmission and maximize machine uptime (coupling, bearing, and seal life).

Obwohl Kupplungen klein und teuer sind, spielen sie im Fertigungsprozess eine wichtige Rolle. Sie müssen leicht zu verbinden und zu trennen sein und einen gewissen Fluchtungsfehler zwischen zwei benachbarten Wellen tolerieren. Der Zweck einer Kupplung besteht darin, die Restfehlstellung in der laufenden Bewegung zu minimieren, um die Kraftübertragung zu optimieren und die Maschinenverfügbarkeit (Kupplungs-, Lager- und Dichtungslebensdauer) zu maximieren.