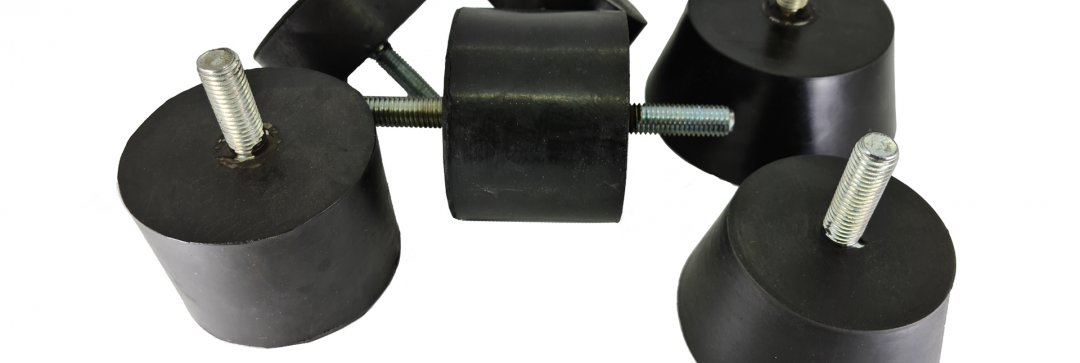

Vibration mounts are rubber elements that prevent transmission and reduce noise by dampening vibration and impacts generated by the mechanisms they are installed in. Vibration mounts absorb axial and radial forces, protecting the mechanism and its components, and ensuring their longevity.

Dangers of Vibrations

Large motors and industrial machinery can generate strong vibrations and excessive noise. These vibrations damage equipment and create unsafe working conditions. Consequently, they can negatively impact product quality and even halt production.

Vibration Isolation Parts and Their Functions

Vibration isolators protect your machinery by reducing the amplitude and frequency of vibration waves. Acting like shock absorbers, these components ensure smooth and efficient operation of engines and machinery. They are typically made of elastomer materials such as natural rubber and can be used with metal mountings.

Areas of Use of Vibration Mounts

Vibration mounts can be used wherever impact work is present. Various applications include:

- Machine connections: Connections between machine parts

- Contact with the ground: Maintaining the balance of the machines

- Industrial equipment: Conveyor systems, ventilation systems, generators, shock absorbers, medical devices

- Pump and hydrophore systems: Marine equipment, press benches

General Application Areas:

- Pump

- Receptacle

- Roller Mills

- Cameras

- CNC Machines

- Military Equipment

- Washing Machines

- Industrial Boat Engines

- Small Electric Motors

- Vibrating Tables

- Ventilation Equipment

- Aviation Equipment

- Compressors

- Transformers

- Shipping Containers

- Defense Equipment

- Marine Fortification Engines

Vibration mounts can be manufactured in both bolted and boltless versions and are used in many sectors to provide effective vibration and impact prevention.